Injection Mould Tools come in many forms, from small simple tools not much bigger than a shoebox, to giant tools the size of an elevator, weighing several tons.

At FirstPress we know that tool design is key to a quality result. The time and effort put into the tool design and manufacture is greatly rewarded with a far superior end result. Whether it be an aluminium tool for small quantity runs or a fully-hardened steel tool designed for long life and high quantities, we have the expertise to get it right first time.

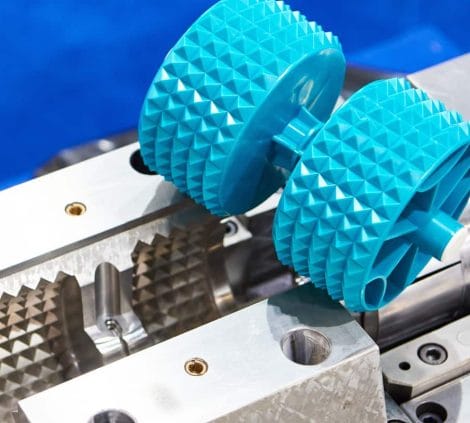

Precision tooling is the foundation of high-quality plastic moulding. Our in-house tooling department designs and manufactures robust moulds tailored to specific project requirements, ensuring efficiency, repeatability, and extended tool life.

We use high-grade tool steels and advanced machining techniques, such as CNC milling and EDM, to produce durable moulds capable of handling high-volume production.

Regular maintenance and servicing ensure that our tooling maintains peak performance, delivering consistent and defect-free parts.