Before any full production run, prototypes and sample mouldings are produced and presented to the customer. This gives the customer the opportunity to examine the full size product sample, checking the colour and textured finish for example, ensuring it meets with their expectations.

It is at this stage that we also check the quality of the end product and ensure that there are no minor defects present. At this stage we can still make minor changes to the mould tool if required.

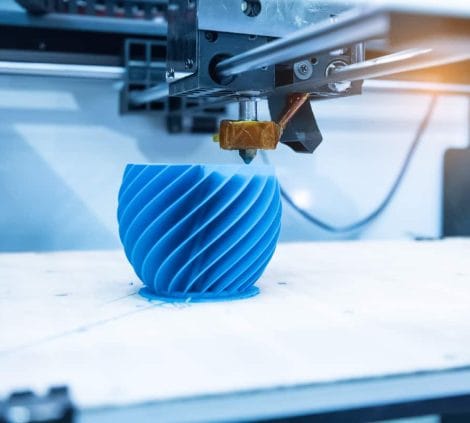

We provide rapid sampling and prototype production to validate designs before full-scale manufacturing. This allows for testing, refinement, and performance verification, minimising risk and ensuring final product excellence.

Our prototyping services include 3D printing, soft tooling, and pre-production runs, allowing clients to assess form, fit, and function before committing to full-scale production. By conducting thorough testing and evaluation, we help clients refine their designs and accelerate time to market.