In addition to a full spectrum of plastic injection moulding services, we also provide a complete assembly service of additional component parts, such as threaded inserts for example. failures can occur due to … Brass and aluminium are common choices. for example when printing, labelling, assembly and packaging

It is at this stage that we also check the quality of the end product and ensure that there are no minor defects present. At this stage we can still make minor changes to the mould tool if required.

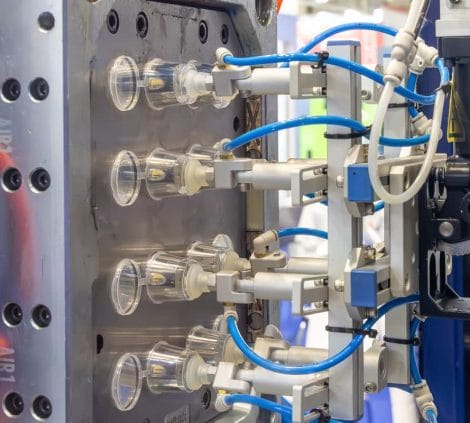

Our advanced plastic injection moulding processes deliver consistent, high-precision components across a wide range of applications. We also offer secondary operations, including assembly, ultrasonic welding, and insert moulding, ensuring a complete manufacturing solution.

Our automated production lines maintain high efficiency and repeatability, while our skilled technicians oversee quality control at every stage. Whether producing simple or complex assemblies, we integrate multiple components seamlessly, reducing additional processing time and costs.